The temperatures of the gases inside flue ducts are up to 300 °C. Gases can contain sulphur and other corrosive substances. Install thermal insulation in the support structure of the flue duct to prevent the surface temperature from dropping to the point where the gasses condense and form corrosive acidic deposits.

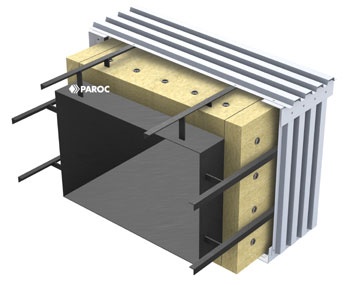

High flow speeds, temperature fluctuations and pressure together with the sheer size of the ducts and equipment, require high mechanical strength from the structures. For flue ducts, Paroc recommends you use double layer insulation in order to prevent cold bridges that increase the risk of corrosion. Usually, both layers are slabs but it is possible to combine slabs with wired mats. The optimal insulation material depends on the temperatures and type of flue duct in question.

|

|

For flue ducts Paroc recommends the following solution:

- Use one or double layer insulation solution with 80 kg/m3 PAROC Pro Slabs.

- Fix the insulation with welded pins.

PAROC Pro Slabs provide superior thermal insulation at high temperatures and good mechanical strength. For rectangular ducts, slabs are easier to install but wired mats can also be used.

|

| Flue ducts are easy to insulate with slabs, in either one layer or multilayer insulation solutions. The slabs are fixed with pins and washers. |