Boiler and insulation solutions must allow for heat expansion. The casing and plumbing of boilers are constantly moving due to heat expansion and vibrations. Attached equipment, such as burners and fans, cause vibration. In addition to the very high temperatures of the boiler, temperatures can vary significantly in different parts of the structure.

The right insulation solution reduces heat loss in the boiler and prevents overheating of the boiler room, all of which increases boiler efficiency. Design the insulation solution based on the boiler type and specifications of the boiler manufacturer. According to standards, boilers should be insulated with two to three layers of insulation and the insulation thickness should be in total 200–300 mm.

When started up for the first time after insulation has been installed, do not heat the boiler should quicker than 50 °C in an hour.

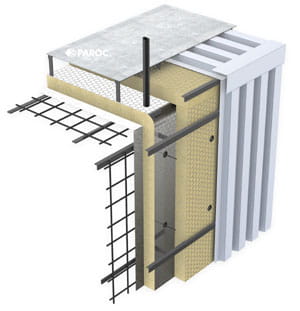

Boiler pipe wall

Due to the high temperatures involved, two to three layers of insulation are required in order to provide a solution that is strong and thick enough. Vibrations also require special care when mounting the installation.

The insulation material should be flexible in order to fill all the gaps and allow for heat expansion. Install aluminium foil n between the insulation layers to prevent heat radiation inside the insulation. PAROC stone wool products have good thermal properties to withstand very high temperatures as well as big varieties in temperatures in different parts of the boiler.

|

For boiler pipe walls Paroc recommends the following solution:

- Use two layers of 120 mm 100 (or 130) kg/m3 PAROC Pro Wired Mat with aluminium foil facing. Another alternative is to use 80 kg/m3 PAROC Pro Slabs as a top layer.

- The insulation structure is normally faced with corrugated steel or aluminium cladding.

- Fix the insulation of the pipe wall with pins welded to the pipe wall.

|

Boiler penthouse

The tops of boilers feature a series of pipe junctions. Insulate these pipe junctions with a special insulation structure for the boiler penthouse.

The main structure is made of flat bars and heavy duty steel net and is normally insulated with wired mats or wired mats and slabs. The whole structure is coated with heavy-duty corrugated steel plates. The steel plates on top bear the weight of maintenance workers.

|

For boiler penthouse Paroc recommends the following solution:

- Use two layers of 120 mm 100 (or 130) kg/m3 PAROC Pro Wired Mat with aluminium foil facing. Another alternative is to use 80 kg/m3 PAROC Pro Slabs as a top layer.

- Fix the insulation with pins and washers.

|